Industry 4.0 / IIoT

The industry is undergoing significant digital advancement, therefore many companies are implementing IoT systems to digitalize their processes, products or production.

What is Industry 4.0?

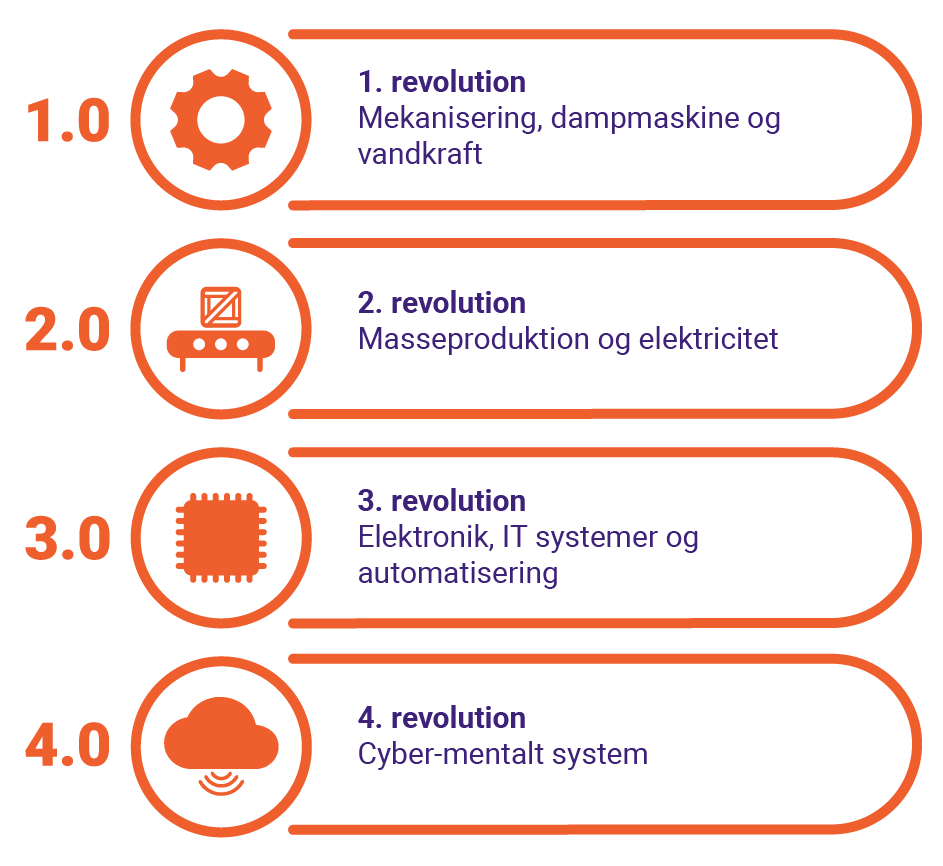

Industry 4.0, also referred to as Industrial Internet of Things (IIoT), is recognized in the industry as the fourth industrial revolution. This follows the automation of machines and processes in Industry 3.0, which was a significant development in the industry. Industry 4.0 serves as a link between the digital world and the physical production within businesses. The image illustrates the different industrial revolutions the industry has gone through.

Industry 4.0 enables businesses to digitize their production processes and enables them to gather valuable data from their machines and robots. Sensors and visualizations provide a comprehensive overview of the production process. The data collected can help manage and prevent production disruptions. For example, the data can help answer questions such as: why did the machine stop? what is the average operating time? what led to the disruption? The successful implementation of Industry 4.0 is one of the key factors for businesses' current and future competitiveness and innovation capacity.

In the industry, the concept of "Digital Twins" can also be utilized. It refers to a complete digital modeling of the production process or parts thereof. With the digital model, changes to the production flow can be simulated and the impact on the actual pipeline can be assessed.

Industry 4.0 in Denmark

The time to invest in IoT is now! The growth of Industry 4.0 in Denmark is increasing annually, as technology becomes more accessible and more companies recognize that digitalization is the way forward. This includes advancements in areas related to the development of new products and services that contribute to sustainability and the green transition.

We are ready to assist with the Industry 4.0 challenges or opportunities that your business faces.

How does a Industry 4.0 project progress at Iterator IT?

As a first step, we will work with you to gain an understanding of your production by conducting a comprehensive overview of your business and production, and subsequently zeroing in on a specific focus area to begin with.

We often observe that large amounts of data collected in different systems go unused. This can be in legacy systems, your ERP solution, or even in the production machines themselves - this is what we first attempt to identify. There is often valuable data from several years back that can be utilized. On several occasions, we have been involved in integrating with very old systems to take advantage of historical data, and so that the customer does not have to replace everything at once.

The next step is to identify the data we want to collect. This may involve collecting data from a PLC or installing a new sensor to measure something.

We assist in selecting what to investigate based on specific optimization points and challenges/issues/tasks (use cases). This way, we let the specific use cases guide the direction of development, so we don't go off course.

When we initiate the development, we will typically work in short sprints, where we frequently return to you and display how much progress has been made and what insights have been gained along the way.

How do we create value for you

Down time in the production machinery is expensive. If you can get a complete overview of when the production stops, not to mention why, you can begin optimizing production, leading to direct cost savings.

By having in-depth data on all aspects of production, you also have a basis for analyzing how different decisions will affect the outcome. Additionally, it provides measurable KPIs with concrete numbers - so you move from making decisions based on intuition to making them based on concrete numbers.

It also enables you to accurately measure the impact of changes on your output.