Case

Skiold Digital

Intelligent IoT system for automation and management of pig production

Skiold Digital is a cutting-edge and innovative IoT and management system. It primarily provides farmers with the capability to consistently monitor their assignments, oversee their machinery and equipment, and have the ability to intervene in the event of any unfavorable patterns.

- The case description

Skiold aimed to develop a system that would make the daily life of farmers easier and more efficient, while also reducing incidents that could hinder their daily operations.

Furthermore, Skiold also desired to provide their customers with even better products and services that meet their needs. Hence, data directly from their customers' farms could make a significant difference.

Hours

Hours spent in total so far

Skiold

Manufacturing company

Tools and equipment for agriculture

Danish company

+500 employees

How we solved it

Skiold has developed an innovative IoT and management system that can actively be used in modern piggeries. It is an intelligent data platform designed for agriculture that integrates management systems and control systems into a single platform. The system continually gathers data, which ultimately leads to informed decision-making based on precise analysis. Skiold's IoT project is based on a personalized modular system, which allows for customization to meet individual needs.

For example, modules such as:

- Inventory management

- Feeding

- Medication

- Purchasing

- Task management

- Preventive maintenance

- Analysis modules

Our responsibilites

UI/UX design

System architecture

Cloud architecture and hosting

IoT development (Backend and IoT edge)

Software development (Web, App & Backend)

Technologies

Skiold Digital is a modular IoT solution that is continuously developed with new additions to keep it up-to-date. In the development of the system, we have integrated Skiold's existing control systems and management systems across the divisions of the company. Today, the product encompasses data-entry, control system, management system, business intelligence and analysis system.

With Microsoft Azure, the existing systems of the farm are connected to the Cloud, allowing for intelligent and automated control and data collection from both production facilities and feed mills. The entire system is hosted in Skiold's Azure Subscription using Azure IoT Hub, Docker containers in Azure Container Services, and Azure Active Directory B2B

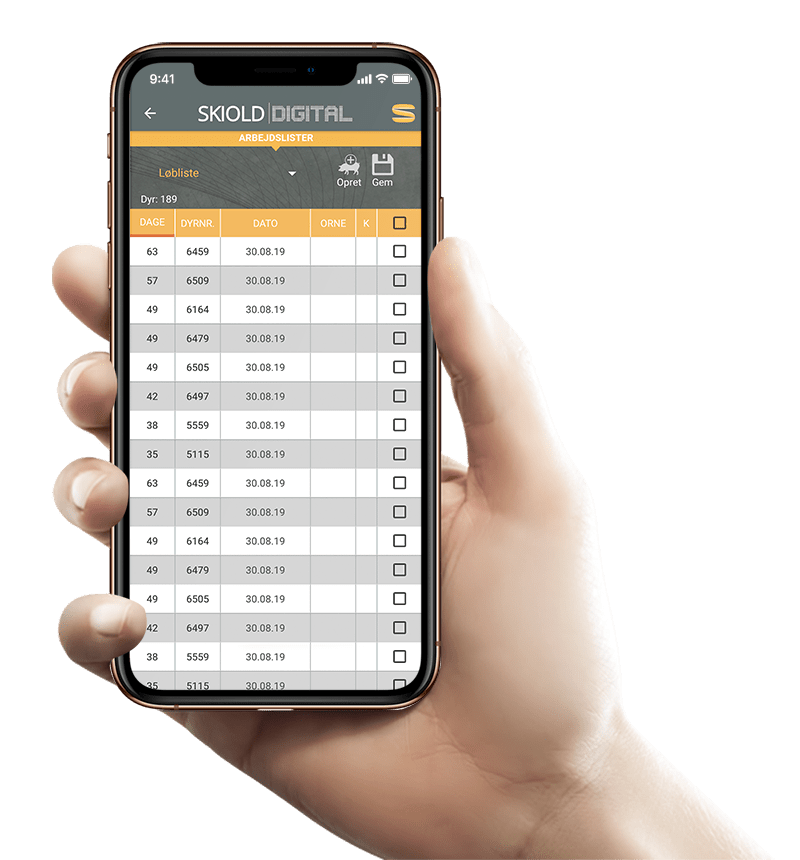

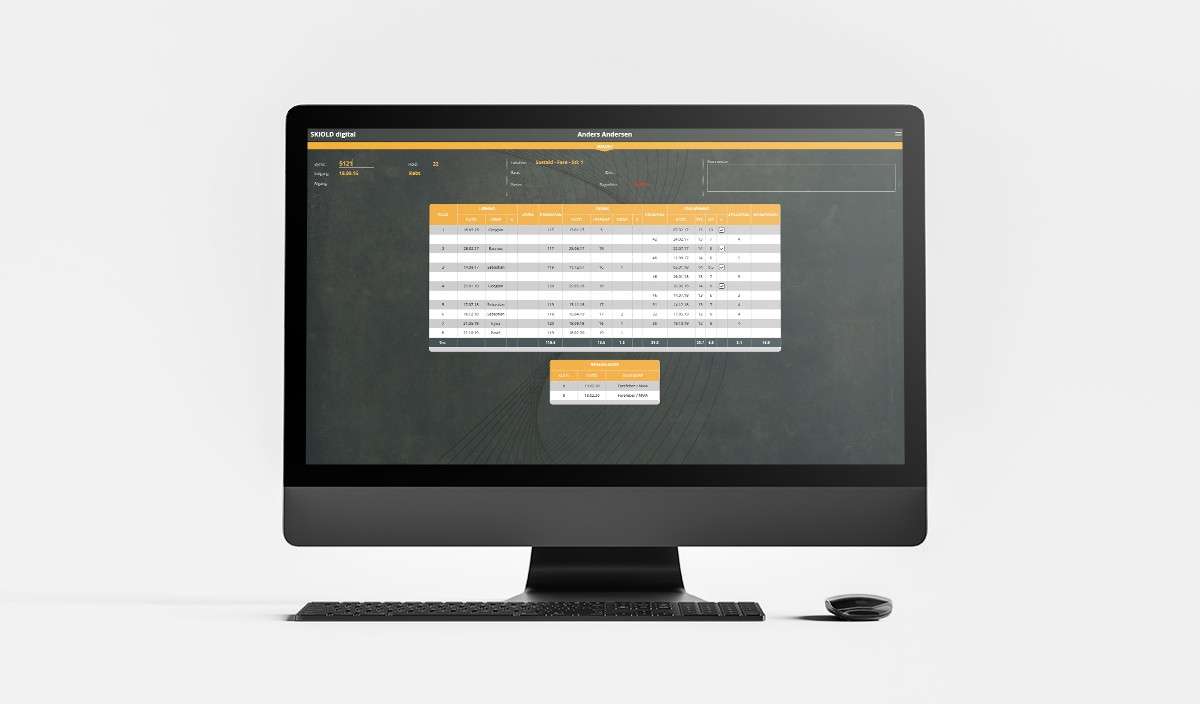

To support the IoT system, an extensive "Pig Management" system has been developed for the registration of all animals and events in the herd. The system has been created using ASP.NET Core, React, and React Native and is available both as a native app on Android and iOS and as a portal as a Single Page Application. In collaboration with Skiold's competent professionals, a concept has been developed that supports the workflows of pig farmers/users and at the same time makes it easy and intuitive to carry out the required registrations. The web portal contains customized reports and insights.

The results

Skiold is now capable of offering their customers the ability to manage and control their farm based on accurate data analysis collected from their farm specifically. Additionally, their customers can now control feed directly from the barn, instead of from a computer elsewhere on the farm.

The purpose of Skiold Digital is to personalize each system as much as possible to each farm, so that farmers receive only the information they need to optimize their processes. In addition, they can monitor animals and machinery to respond to unusual patterns before they have consequences. The system can also send notifications when it is time to change machine parts.

Skiold can now use the collected data to optimize their own products, and their customers can benchmark against other Skiold customers to evaluate their farm's process improvement opportunities.